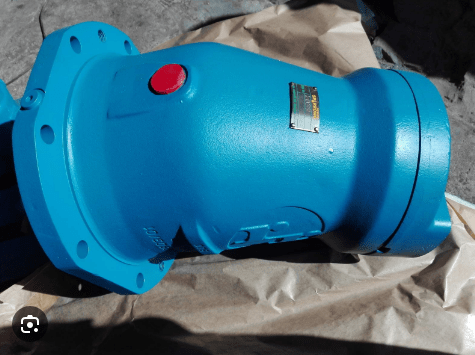

The Rexroth A2F500 hydraulic pump is an essential part of heavy machinery operations today. It is a powerful hydraulic component that provides excellent performance in various industries, including construction and mining.

The success of your operations depends on the reliability of your A2F500 pump. To ensure its optimal performance and longevity, high-quality repair parts and kits are crucial. They help in:

However, finding the right repair parts for your Rexroth A2F500 can be difficult. There are many options available in the market, but not all parts meet the strict quality standards required for these precision-engineered pumps.

In this guide, we will walk you through the process of selecting the best repair parts and kits for your A2F500 pump. This knowledge will enable you to maintain peak performance and reliability. Whether you are performing routine maintenance or addressing specific problems, understanding your choices between genuine parts and trustworthy alternatives will help you save time and resources.

The Rexroth A2F500 hydraulic pump is a highly precise engineering marvel. This axial piston pump has:

The A2F500’s design incorporates a swashplate mechanism that enables variable displacement, making it ideal for:

Understanding the pump’s working principles is crucial for maintenance. The A2F500 operates through a rotating cylinder block containing multiple pistons. As the block rotates, these pistons move against an angled swashplate, creating the pumping action that powers hydraulic systems.

A real-world example showcases the A2F500’s reliability: In a mining operation, an A2F500-equipped excavator maintained consistent performance for over 10,000 hours with minimal maintenance requirements. This exceptional durability stems from its:

The pump’s ability to maintain stable pressure and flow rates under varying load conditions makes it a preferred choice for demanding applications where performance consistency is paramount.

For more insights into hydraulic systems and their applications, you might find this Kawasaki magazine article interesting as it delves deeper into the subject matter.

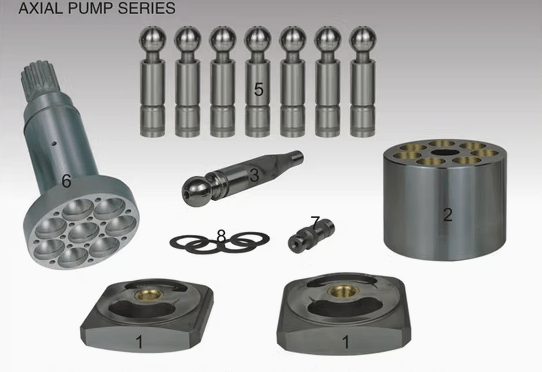

A complete repair kit for the Rexroth A2F500 hydraulic pump contains critical components designed to restore optimal functionality. Let’s explore these essential elements:

Each component plays a vital role in the pump’s operation. The valve plates control fluid flow, while cylinder blocks house the pistons that generate hydraulic pressure. The disc springs maintain proper tension, and set plates ensure accurate component alignment.

When it comes to replacing parts in your A2F500 hydraulic pump, you have two main options: OEM (Original Equipment Manufacturer) parts or aftermarket alternatives. Here’s a breakdown of the differences between the two:

Regardless of whether you choose OEM or aftermarket parts, it’s essential to ensure that the replacement components meet strict quality standards. Here’s how premium manufacturers maintain quality assurance:

Premium manufacturers maintain strict quality control measures throughout production. Their facilities utilize advanced machinery from Germany and Japan, ensuring precise tolerances and superior finish quality.

The manufacturing process adheres to international standards:

These rigorous standards guarantee that replacement parts match original specifications in:

Reputable suppliers conduct extensive testing under simulated operating conditions. Their test procedures include:

Finding reliable suppliers for A2F500 hydraulic pump parts requires careful consideration of several key factors. Many authorized distributors maintain extensive inventories to meet immediate customer needs, with real-time stock monitoring systems ensuring accurate availability information.

Leading suppliers implement rigorous quality control measures throughout their supply chain. Each component undergoes detailed inspection processes before shipment, ensuring compatibility with OEM specifications. These suppliers typically offer:

Many suppliers now utilize digital platforms for streamlined ordering processes, allowing customers to:

The availability of specialized testing facilities at select suppliers enables customers to verify part performance before large-scale deployment. These testing services include pressure testing, flow rate analysis, and compatibility verification with existing systems.

The price range for A2F500 repair kits varies significantly across suppliers, influenced by several key factors:

The quality of the components used in the repair kits can greatly impact the pricing. Suppliers may offer:

The specific configuration of the repair kit also plays a role in determining its price. Different suppliers may offer:

What is included in the package can vary between suppliers and affect the overall cost. Some common inclusions are:

The way in which suppliers source their products can influence pricing as well. Factors such as:

can all impact the final cost of the repair kits.

In addition to the core offerings, some suppliers may provide additional services that come at an extra cost. These service add-ons could include:

These pricing variables help buyers select packages that align with their maintenance requirements and budget constraints. Different suppliers offer varied combinations of these elements, creating distinct value propositions in the market.

Seal kits are crucial in A2F500 hydraulic pump systems. These specialized components create a barrier against fluid leakage while keeping pressure levels optimal within the system.

These seals are strategically placed to create multiple layers of protection, shielding the pump’s internal parts from contamination and stopping costly fluid losses.

Different operating conditions require specific sealing solutions. The A2F500 pump uses various sealing materials, each designed for different performance characteristics:

The choice of material directly affects seal performance and lifespan. High-quality sealing materials can withstand:

Modern seal kits use advanced compounds that combine multiple beneficial properties. These hybrid materials offer increased durability while remaining flexible in various operating conditions.

When selecting seals for the A2F500 pump, consider the following factors:

Regularly inspecting and replacing seals can help prevent unexpected failures. Quality seal kits come with detailed installation guides and material compatibility charts to ensure proper implementation.

The Rexroth A2F500 hydraulic pump powers an impressive range of heavy machinery across multiple industries. Let’s explore its real-world applications and maintenance implications:

The A2F500’s versatility shines through its adaptability to different working conditions. From dusty construction sites to temperature-controlled manufacturing facilities, this pump maintains consistent performance when properly maintained with quality repair parts.

Proper maintenance scheduling directly affects operational efficiency. Here’s how quality repair parts influence maintenance practices:

Regular Inspection → Early Issue Detection → Timely Parts Replacement → Minimal Downtime

The availability of high-quality repair parts enables maintenance teams to:

Machine operators report significant improvements in equipment reliability when using genuine repair parts. A well-maintained A2F500 pump can operate efficiently for extended periods, reducing the frequency of repairs and associated costs.

The pump’s performance directly impacts productivity levels across various applications. Construction projects stay on schedule, manufacturing lines maintain production targets, and mining operations achieve extraction goals when equipment operates at peak efficiency.

To keep your Rexroth A2F500 hydraulic pump running smoothly, you need top-notch repair parts and kits. The right components will protect your investment and ensure reliable operation in tough situations.

Key things to remember for maintaining your hydraulic system:

We invite you to connect with other maintenance professionals in our community. Share your experiences with A2F500 repairs or ask specific questions about component selection. Your insights help build a stronger knowledge base for hydraulic system maintenance.

The Rexroth A2F500 hydraulic pump is crucial for ensuring the performance and reliability of hydraulic systems in heavy machinery. Its design and features contribute to efficient operation across various applications, making it a key component in equipment such as excavators and loaders.

A typical repair kit for the A2F500 hydraulic pump includes essential components such as valve plates, cylinder blocks, and seals. These parts play vital roles in the pump’s operation, ensuring optimal performance and minimizing downtime during maintenance.

Using OEM parts ensures that replacement components match original specifications, which is critical for proper fitment and functionality. OEM parts often undergo rigorous quality testing and adhere to strict manufacturing standards, providing greater reliability compared to some aftermarket alternatives.

Seal kits are essential for preventing leaks and maintaining system integrity in hydraulic systems. They are made from durable materials that resist heat and oil, ensuring longevity and effective sealing under various operational conditions.

Pricing variability for A2F500 repair kits can be influenced by factors such as the components included in the kit, packaging options offered by suppliers, stock availability, and additional services like technical support or warranty coverage.

Access to quality repair parts significantly affects maintenance schedules by minimizing downtime. Reliable components allow for timely repairs, which enhances operational efficiency and reduces disruptions in heavy machinery usage.

“Order Top-Quality Parts Today!”