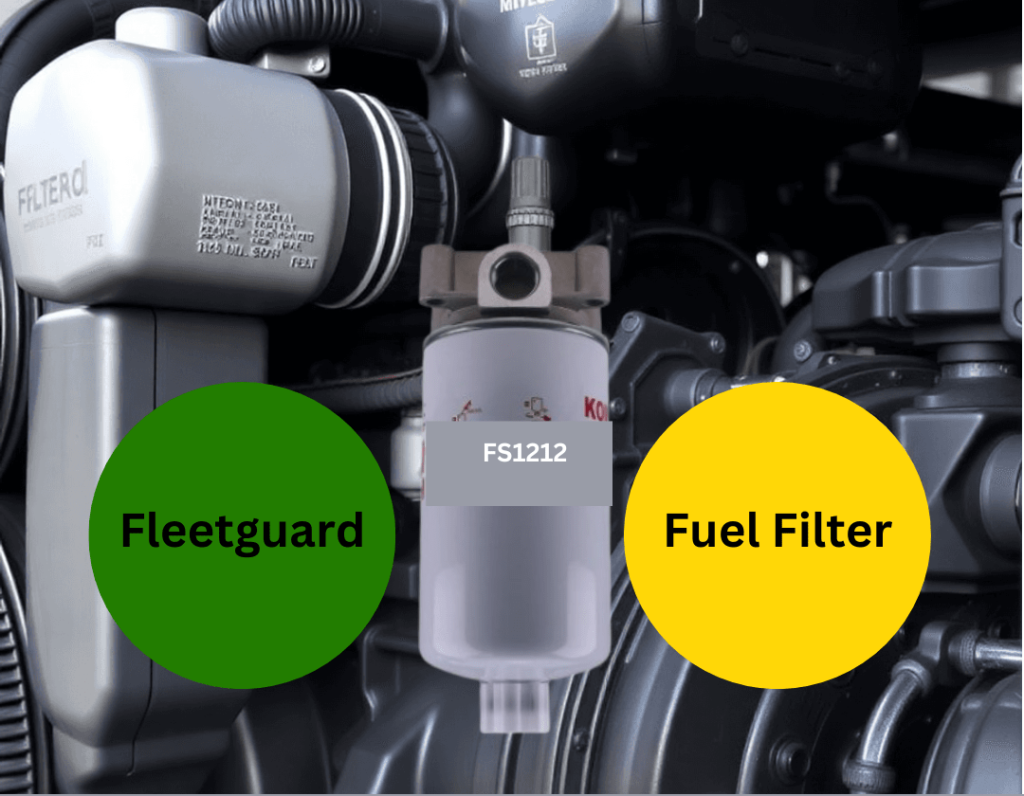

To keep your diesel engine running at its best, you need to pay close attention to the quality of fuel you use. That’s where the Fleetguard FS1212 Fuel Filter comes in – it’s like a superhero for your fleet, protecting against harmful substances that can damage your engines.

This powerful filter is designed with both cutting-edge technology and tough durability in mind. Here’s what it can do:

The FS1212 isn’t just another filter – it’s a complete defense system for your diesel engines. Its high-capacity filter media tackles dirt, debris, and water before they can compromise your engine’s performance or cause costly damage.

What makes this filter truly special? You’re about to discover:

Whether you manage a commercial fleet, operate heavy construction equipment, or run marine vessels, the Fleetguard FS1212 Fuel Filter delivers the protection your engines need. Let’s explore how this robust filtration solution can transform your fleet’s reliability and efficiency.

Clean fuel is essential for the proper functioning of diesel engines. When fuel becomes contaminated, it can cause significant damage to vital engine parts. Here’s a breakdown of what happens when impurities enter your fuel system:

Even a single contaminated fuel tank can set off a series of expensive problems:

Let’s take a look at some potential expenses you could face due to poor filtration:

These figures highlight the financial impact that contaminated fuel can have on your operations.

Investing in high-quality filtration solutions such as the Fleetguard FS1212 can provide an effective defense for your engine. This advanced filter uses cutting-edge technology to capture various contaminants:

By incorporating regular maintenance practices alongside premium filters into your fleet management strategy, you can establish a strong protection plan for your vehicles.

The superior design of the FS1212 filter offers several advantages:

This proactive approach helps prevent minor issues from escalating into major repairs, ultimately saving you both time and money in the long run.

The Fleetguard FS1212 Fuel Filter is an innovative solution for diesel engine filtration. Its unique features provide a strong defense against fuel contamination, raising the bar for engine protection.

The FS1212’s advanced filtration system uses a multi-stage process to effectively capture and isolate contaminants:

The filter’s enhanced media capacity delivers exceptional performance metrics:

Despite its space-saving dimensions, the FS1212 packs impressive capabilities:

The FS1212’s water separation capabilities set it apart from conventional filters:

Each FS1212 filter undergoes extensive quality assurance:

The Fleetguard FS1212 Fuel Filter proves its worth across multiple industries, delivering exceptional performance in diverse operational environments. Let’s explore how different sectors benefit from this advanced filtration system:

The FS1212’s high-capacity filter media excels in these demanding applications by:

The compact design proves particularly valuable for:

Each industry benefits from Fleetguard’s rigorous durability testing, ensuring the FS1212 maintains peak performance even under extreme conditions. The filter’s robust construction withstands:

This versatility makes the FS1212 fuel filter an ideal choice for fleet managers seeking reliable filtration across diverse applications and operating conditions. Particularly for those utilizing fleet management software for rental businesses, the FS1212 can significantly enhance operational efficiency and reduce unexpected vehicle downtime.

Marine engines and mining equipment face intense operational demands that put extraordinary stress on fuel systems. The harsh saltwater environment in marine applications creates unique challenges:

Salt-laden air accelerates wear on engine components

Increases risk of water contamination in fuel tanks

Wave action stirs up sediment in fuel tanks

Mining operations present their own set of demanding conditions:

The Fleetguard FS1212’s advanced filtration system excels in these challenging environments. Its high-capacity filter media captures harmful particles while maintaining optimal flow rates, critical for continuous operations. The filter’s exceptional 90% emulsified water separation capability proves invaluable in marine settings, where water contamination poses a constant threat.

The compact design fits seamlessly into tight engine compartments common in marine vessels and mining equipment, while durability testing ensures reliable performance under extreme conditions. This robust construction withstands intense vibration and pressure fluctuations typical in heavy-duty mining operations.

Proper maintenance of your FS1212 fuel filter maximizes its advanced filtration capabilities and extends its service life. Here’s a comprehensive maintenance schedule to protect your investment:

Following these maintenance guidelines ensures your FS1212 filter maintains its high-capacity filtration capabilities and emulsified water separation efficiency, protecting your engine investment through optimal performance.

Proper fuel management practices amplify the effectiveness of your Fleetguard FS1212 fuel filter. Here’s your essential guide to maintaining clean, high-quality fuel:

These practices create a robust defense against fuel contamination. When combined with the advanced filtration capabilities of the FS1212 filter, your fleet benefits from maximum protection and optimal performance.

The performance of your fleet depends on the small but important decisions you make – and choosing the right fuel filter is one of the most important. The Fleetguard FS1212 fuel filter is a complete filtration solution that offers great value through:

Investing in high-quality filters like the FS1212 will bring you benefits such as:

Smart fleet managers understand that cutting corners on filtration quality can result in higher costs later on. The Fleetguard FS1212 fuel filter is your trusted partner in keeping your engines running at their best and protecting your valuable assets. Make the smart choice that ensures your fleet operates smoothly – choose the FS1212 for all your filtration needs.

The Fleetguard FS1212 Fuel Filter is a complete filtration solution designed to maintain optimal diesel engine performance by effectively removing contaminants from fuel.

Fuel filtration is crucial because fuel contamination can negatively impact engine performance, leading to costly repairs and increased maintenance costs. Regular maintenance with high-quality filters like the FS1212 helps manage these issues.

The FS1212 features an advanced filtration system, high-capacity filter media, compact design, and emulsified water separation capabilities, all contributing to its superior filtration efficiency and durability.

The FS1212 filter excels in various industries including agriculture, construction, marine applications, and mining, providing reliable fuel supply and minimizing downtime for commercial vehicle fleets.

To ensure optimal performance, it’s recommended to follow a regular inspection schedule and replace the filter as needed. This includes checking for signs of wear and contamination regularly.

Best practices include proper fuel storage techniques to prevent contamination, regular inspections of fuel filters like the FS1212, and implementing a systematic maintenance routine to enhance overall efficiency.