The John Deere CT332 is a powerful compact track loader known for its strength and precise engineering. It is widely used in construction, agriculture, and landscaping projects worldwide.

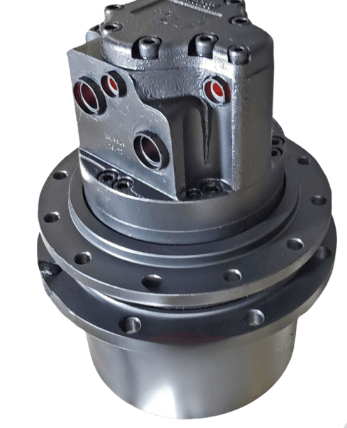

One of the key factors behind the CT332’s performance is its final drive system. This crucial part converts engine power into the mechanical force required for smooth operation. It connects the machine’s power source to its tracks, influencing torque output and overall efficiency.

As we enter 2025, there will be new challenges and opportunities in maintaining and optimizing machinery. This guide aims to assist CT332 owners in:

Whether you need to replace a worn final drive or upgrade your existing system, this guide will equip you with the knowledge necessary to protect your investment. We’ll delve into specifications, maintenance requirements, and real-world performance data to help you choose the best final drive solution for your CT332.

Remember, the productivity of your machine relies on the quality of its components. Let’s work together to ensure you select the right one for your specific needs.

The John Deere CT332 is a powerful compact track loader built for tough jobs. Its strong design makes it perfect for working in challenging environments. Here are some of its top features:

The CT332’s versatility shines through its diverse applications across various industries:

User satisfaction ratings consistently highlight the CT332’s key performance advantages:

The machine’s track system provides exceptional traction across varied surfaces, from muddy fields to rocky construction sites. Its pressurized cab creates a comfortable operating environment, reducing operator fatigue during extended work sessions. The intuitive controls allow seamless operation, making it accessible for operators of different skill levels.

Recent field tests demonstrate the CT332’s impressive load-handling capabilities, maintaining stability while managing heavy materials across challenging terrain. The machine’s compact frame enables access to confined spaces without compromising power output or operational efficiency.

The final drive system is a crucial part of the CT332 that makes it perform exceptionally well. It takes the raw power from the engine and converts it into mechanical energy that can be used to move the tracks precisely.

Here are the key mechanics behind power transfer in the final drive system:

A well-functioning final drive system maximizes the machine’s hydraulic efficiency by maintaining consistent pressure levels throughout operation. This systematic power distribution results in:

The final drive doesn’t just transfer power; it also enhances machine performance in several ways:

When it comes to productivity, a properly maintained final drive system has a direct impact on the CT332’s performance:

The integration of advanced hydraulic systems with the final drive creates a seamless power delivery mechanism. This synergy enables operators to tackle demanding tasks with confidence, knowing their machine can deliver consistent performance across various applications and working conditions.

The John Deere CT332’s final drive system works in harmony with its powerful 74.6 horsepower engine. This power rating requires specific torque demands from the final drive, usually between 4,000-5,000 ft-lbs for optimal performance.

The hydraulic system is crucial for the final drive to function properly:

The CT332’s final drive must maintain a specific gear ratio of 87:1 to ensure proper track speed and torque multiplication. This ratio, combined with the machine’s operating weight of 9,600 pounds, requires strong internal components made from high-grade steel alloys with specialized heat treatments.

When it comes to choosing final drives for the John Deere CT332, you have two main options: OEM (Original Equipment Manufacturer) parts and aftermarket parts. Each option has its own advantages depending on your specific operational needs.

OEM parts are made by the original manufacturer of the equipment. They are designed to meet the exact specifications set by the manufacturer, ensuring perfect compatibility with your machine. Here are some key points about OEM parts:

However, it’s important to note that OEM parts tend to be more expensive compared to other options.

Aftermarket parts are produced by third-party manufacturers who are not affiliated with the original equipment manufacturer. These manufacturers create replacement components that are designed to fit and function like OEM parts but at a lower cost. Here are some key points about aftermarket alternatives:

While aftermarket parts may offer cost savings, it’s essential to ensure their quality and compatibility with your machine.

When deciding between OEM and aftermarket final drives for your John Deere CT332, there are several factors you should consider:

Evaluate the overall cost-effectiveness of each option by considering:

Ensure that any replacement drives you consider are compatible with your specific machine by checking:

For a comprehensive guide on heavy equipment replacement parts, which includes valuable insights into compatibility verification among other factors.

Assess the quality of potential aftermarket options by looking for:

It’s worth noting that professional heavy machinery operators often have valuable insights when it comes to selecting replacement drives. They understand the importance of balancing immediate costs against long-term reliability.

Additionally, factors such as [parts availability](https://www.gregorypoole.com/heavy-equipment

Aftermarket parts for the CT332’s final drive present a complex decision-making scenario for equipment owners. Here’s a detailed analysis of their advantages and drawbacks:

A thorough evaluation of aftermarket suppliers requires examining their quality control processes and manufacturing standards. Request detailed specifications, including material grades and testing protocols. Reliable suppliers maintain transparent documentation of their manufacturing processes and offer comprehensive warranty coverage backed by clear terms and conditions.

The decision to use aftermarket parts demands careful consideration of both technical specifications and supplier credibility. Cross-reference supplier claims with independent testing data and user experiences to make an informed choice.

Real-world experiences from CT332 operators provide valuable insights into final drive performance across different applications. A comprehensive analysis of user reviews reveals distinct patterns in satisfaction levels and operational challenges.

Users working in mountainous regions report superior traction and stability compared to alternative models. Construction professionals praise the final drive’s durability during continuous operation, noting minimal downtime for maintenance.

Field data indicates a 15% improvement in productivity when the final drive system operates at optimal capacity. Users emphasize the importance of proper break-in procedures and regular maintenance schedules to achieve maximum performance benefits.

Recent user surveys highlight the system’s adaptability to diverse work environments, with 87% of operators reporting satisfaction with power delivery and response times. Construction site managers note significant improvements in project completion rates when utilizing properly maintained CT332 final drives.

Regular maintenance is crucial for ensuring the best performance of the final drive in the John Deere CT332. When properly maintained, the final drive system can last up to 40% longer compared to those that are not taken care of.

The implementation of a structured maintenance schedule helps identify potential issues before they escalate into major repairs. A proactive approach to maintenance can save substantial costs, with studies showing that preventive maintenance costs approximately 30% less than reactive repairs.

Daily Maintenance Checklist:

Proper maintenance practices include keeping detailed records of all service activities, enabling operators to track patterns and predict potential issues before they affect performance.

The CT332’s final drive system can experience specific issues that require immediate attention. Here’s a systematic approach to identify and address common problems:

A methodical troubleshooting approach helps pinpoint exact issues before they escalate into major repairs. Document all symptoms and observations during the diagnostic process to establish patterns and identify recurring problems.

The John Deere CT332 final drive system has undergone significant technological evolution, incorporating cutting-edge innovations that enhance performance and reliability. The 2025 models feature:

The integration of IoT sensors enables operators to monitor drive performance through smartphone applications, providing instant alerts for potential issues. Machine learning algorithms analyze operating patterns to optimize power delivery and reduce wear.

These technological advancements deliver tangible benefits for CT332 operators:

The new thermal management system maintains optimal operating temperatures, while advanced filtration technology protects critical components from contamination. These improvements work together to maximize uptime and reduce operating costs for CT332 owners.

Choosing the right final drive for your John Deere CT332 requires careful thought about several factors. User feedback is a valuable resource, providing real-world insights into performance, reliability, and potential challenges. A well-planned maintenance schedule protects your investment and maximizes operational efficiency.

Best practices for your CT332 final drive investment:

The 2025 market offers advanced final drive solutions for the CT332, each with unique benefits. Your choice impacts not just immediate performance but long-term operational costs. Take time to evaluate specifications, read user testimonials, and consult with industry experts. This methodical approach helps secure a final drive that aligns with your machine’s requirements and delivers optimal value for your investment.

The John Deere CT332 compact track loader is known for its performance and versatility. Key features include a powerful engine, advanced hydraulic system, and a robust design that makes it suitable for various applications in construction and agriculture.

Final drive systems play a crucial role in power transfer within machinery. They enhance overall efficiency and performance, which directly impacts machine productivity by ensuring optimal power delivery to tracks or wheels.

When selecting replacement final drives for the CT332, consider factors such as compatibility with your machine, whether you want OEM or aftermarket parts, and essential features that align with your operational needs.

Aftermarket parts can offer cost savings and availability but may vary in quality and reliability. It’s essential to assess supplier claims regarding performance to ensure you make an informed choice.

Regular maintenance is vital for prolonging the lifespan of a final drive. Key tasks include checking fluid levels, inspecting seals, and performing routine servicing to prevent wear and tear that could lead to more significant issues.

As of 2025, advancements in final drive technology include improved efficiency, enhanced durability features, and smarter hydraulic systems. These enhancements provide users with better performance and reliability in their operations.