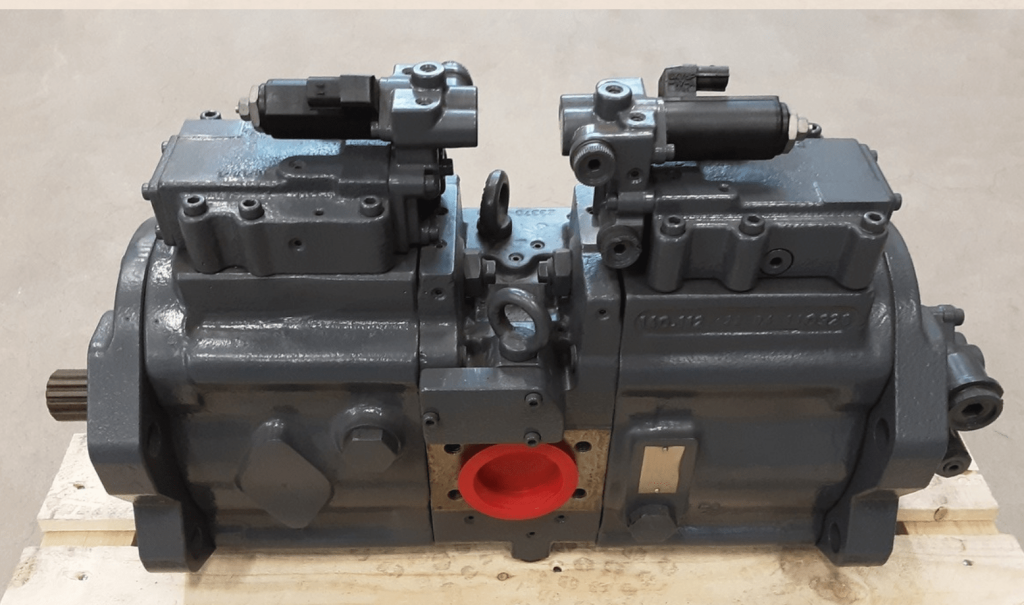

The Kawasaki K3V112DT hydraulic pump is recognized for its power and dependability, making it an excellent choice for excavators from brands like Doosan, Sumitomo, and CASE. With advanced hydraulic efficiency and adaptability, the K3V112DT is perfect for heavy-duty applications across industries like construction, mining, and material handling. This guide provides an in-depth look at its features, installation process, compatibility, and maintenance tips to help you get the most from your excavator. By understanding the K3V112DT’s capabilities, you can maximize productivity on demanding projects and prolong your machine’s lifespan.

Looking to enhance your excavator’s performance? The Kawasaki K3V112DT hydraulic pump could be the upgrade you need. Read on to discover its unmatched benefits!

The K3V112DT pump features an advanced variable displacement design, which allows operators to adjust the flow rate according to specific job requirements. Unlike fixed displacement pumps, this model provides precise hydraulic output, enhancing fuel efficiency while delivering optimal power for demanding applications. This feature makes it an excellent choice for those who prioritize performance and cost savings.

This pump’s design is geared towards minimizing energy waste while maximizing output. The variable displacement not only reduces fuel consumption but also supports longer working hours without compromising the pump’s power or efficiency. Its innovative approach to hydraulic efficiency helps reduce operational costs, an essential advantage for businesses.

Upgrade your hydraulic efficiency today! The K3V112DT is engineered for performance and savings—experience the difference with this advanced pump.

One of the standout features of the K3V112DT is its high flow rate. This capability enables rapid hydraulic response, making heavy-duty tasks faster and more efficient. The pump’s low-noise operation reduces worksite noise pollution and contributes to a more comfortable and less stressful working environment.

Built with resilient materials, the K3V112DT pump is designed to withstand rigorous tasks and high-pressure conditions. This durability makes it a top choice for operations in harsh environments where reliability is critical. By investing in a pump that’s built to last, you can reduce downtime and maintenance costs over the long term.

Experience the power of durability. Equip your excavator with the K3V112DT pump for reliable, long-lasting performance. Get yours from a trusted supplier today!

The Kawasaki K3V112DT is compatible with various popular excavator models, such as Doosan’s DH200 and DX225, Sumitomo’s SH200, and CASE’s CX210. Using OEM parts like the K3V112DT ensures seamless integration, which helps maintain optimal performance and reliability across different equipment. Choosing the right components is essential for ensuring the excavator functions efficiently and avoids premature wear.

Ensure compatibility and performance! Choosing OEM parts like the K3V112DT pump guarantees a perfect fit and long-lasting efficiency for your excavator.

Installing the K3V112DT hydraulic pump is straightforward with the correct tools and guidelines. Start by cleaning the hydraulic lines to remove any debris that could affect performance. Follow the instructions in the manual, securing each component for reliable operation. Taking the time to install each part correctly prevents future issues and optimizes the pump’s longevity.

Routine maintenance of the K3V112DT pump is critical to keeping it operating at peak efficiency. Regularly check hydraulic fluid levels, replace filters, and inspect for wear or leaks. Timely maintenance ensures that your pump performs reliably and extends its operational life, which is crucial for avoiding downtime in heavy-duty applications.

Keep your equipment running smoothly! Schedule regular maintenance for the K3V112DT to maximize its lifespan and efficiency.

When selecting a hydraulic pump, it’s essential to consider flow rate, pressure rating, and efficiency. The K3V112DT model is designed to excel in these areas, offering high performance for heavy-duty tasks. Ensuring that your pump’s specifications align with your excavator’s requirements can significantly improve performance and reduce operational costs.

Make an informed choice. Choose a hydraulic pump that meets your excavator’s needs for efficiency, power, and longevity.

The K3V112DT offers distinct advantages over other hydraulic pumps for Doosan excavators, including superior efficiency, durability, and noise reduction. While some alternative models may offer initial cost savings, the K3V112DT is a worthwhile long-term investment due to its lower energy consumption and reduced maintenance needs. For operators looking for top-tier performance, this model is often the preferred choice.

Invest in quality. The K3V112DT pump provides outstanding performance and durability, making it a smart choice for excavator operators.

Choosing genuine OEM parts is crucial for maintaining the performance and reliability of your hydraulic pump. OEM parts are manufactured to meet the original design specifications, ensuring compatibility and efficiency. Using authentic components reduces the risk of breakdowns and helps avoid costly repairs.

When sourcing the K3V112DT pump and other Kawasaki components, purchase from trusted suppliers who provide guaranteed OEM parts. Reliable suppliers offer the assurance that each part meets quality standards, contributing to the longevity and safety of your machinery.

Need reliable parts? Source genuine OEM parts for your K3V112DT pump to maintain quality and performance.

In addition to the hydraulic pump, components like valves, filters, and cylinders are critical to an excavator’s hydraulic system. Valves control the fluid’s flow and pressure, filters remove contaminants, and cylinders provide the force needed for various functions. Each of these components plays a role in the overall efficiency of the hydraulic system, contributing to smoother operations and enhanced productivity.

Keep every part in sync! Understanding each component’s role ensures your hydraulic system runs efficiently and reliably.

Regular maintenance, fluid checks, and timely filter replacements are essential for keeping your hydraulic system in top condition. Consistent management prevents issues like leaks or clogged filters, which can affect your machine’s performance. By implementing these techniques, you’ll extend the life of your hydraulic pump and reduce unexpected downtime.

Don’t overlook maintenance! Simple hydraulic management techniques can make a huge difference in performance and longevity.

Fuel injectors and pumps are vital to an excavator’s engine performance. These components ensure fuel is delivered with the right pressure, supporting smooth engine operation and reducing emissions. An efficient fuel system leads to lower fuel consumption and a longer machine lifespan, both of which are critical for the profitability and sustainability of heavy-duty machinery.

Optimize your engine’s efficiency. Proper fuel management not only saves costs but also boosts your machine’s overall performance.

1. How does the Kawasaki K3V112DT differ from other hydraulic pumps?

The K3V112DT hydraulic pump features a variable displacement design that adjusts the flow to meet job requirements. This helps reduce energy consumption and wear. It’s also known for its durability and low-noise operation, making it suitable for long-term heavy-duty tasks.

2. Can I install the K3V112DT myself, or do I need a professional?

While experienced operators may handle installation, it’s recommended to have a professional complete the setup and calibration. This ensures the pump is securely installed and integrated with your hydraulic system for optimal performance.

3. What are the signs that my hydraulic pump needs maintenance?

Signs that your hydraulic pump needs maintenance include reduced flow, unusual noise, or excess heat. These symptoms may indicate fluid level issues, filter clogs, or internal wear that require immediate attention.

4. Why should I choose OEM parts over generic alternatives?

OEM parts are built to match your equipment’s exact specifications, ensuring compatibility and reliability. Although generic parts may offer initial cost savings, OEM parts deliver better long-term performance and fewer compatibility issues.

5. How often should I replace the filters in my hydraulic system?

For optimal performance, check and replace filters every 500-1,000 hours of operation, depending on usage and environmental conditions. Clean filters maintain fluid purity and protect the pump from damage.

“The K3V112DT pump is incredibly durable! I’ve had mine for over a year, and it’s performing just like the day I installed it. The quiet operation also makes a huge difference during long shifts.”

— Ryan D., Excavator Operator

“After upgrading to the K3V112DT, my fuel consumption dropped significantly. It’s been a game-changer in terms of both performance and cost savings.”

— Laura S., Construction Foreman

“With regular maintenance, the K3V112DT has been nothing short of fantastic. It’s efficient, powerful, and easy to maintain.”

— Mike T., Heavy Machinery Operator

FIND Kawasaki K3V112DT HERE

NEXT post