The Rexroth A8V172 hydraulic pump is a powerhouse component in the Sumitomo SH450-2 excavator—a machine designed for heavy-duty industrial tasks. This hydraulic pump enables efficient power transmission across the excavator’s hydraulic systems, critical for its lifting, digging, and maneuvering functions. However, to maintain the SH450-2’s high-performance standards, it’s essential to use top-quality repair parts whenever servicing the pump.

Regular maintenance and timely replacement of wear-and-tear parts ensure the Rexroth A8V172 remains operational and extends its longevity. In this comprehensive guide, we’ll explore why investing in quality repair parts matters, break down the A8V172’s essential components, and offer valuable tips on sourcing reliable suppliers for the best repair parts.

The A8V172 hydraulic pump is a highly durable and efficient unit designed for demanding applications. As part of the Rexroth series, it’s recognized for its reliability in the construction and industrial sectors, especially when paired with the Sumitomo SH450-2 excavator. But what makes the A8V172 so effective?

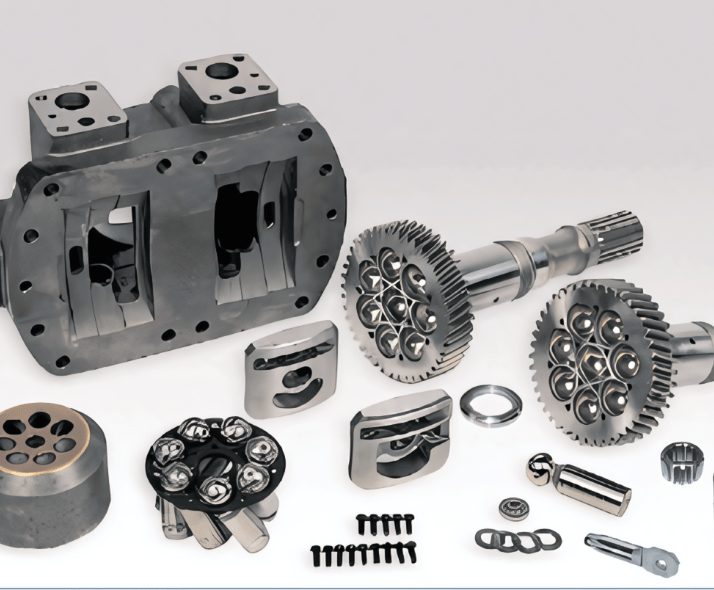

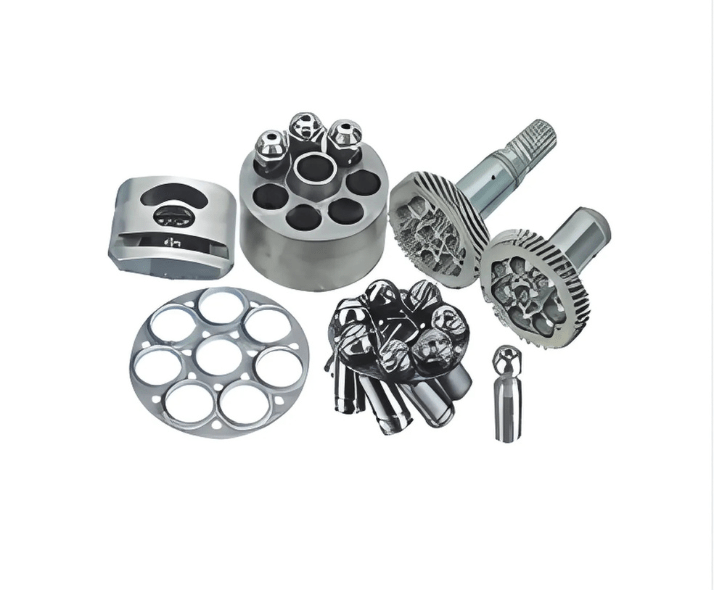

The pump features several key components: pistons, a cylinder block, control valves, and sealing mechanisms. These parts work together to generate hydraulic pressure by converting mechanical energy into hydraulic energy. The cylinder block houses the pistons that move up and down, creating a vacuum effect to draw in and expel hydraulic fluid under high pressure. Control valves regulate this pressure, ensuring fluid flows in the right direction and with the right force, while seals prevent leaks that could reduce system efficiency.

Despite its durability, the A8V172 pump is susceptible to a few common issues, particularly as it undergoes heavy usage. Frequent problems include:

Routine inspections can help identify these issues early on. By replacing worn seals, calibrating valves, and checking for cylinder wear, operators can avoid costly repairs and prevent unexpected breakdowns.

High-quality hydraulic pump repair parts are essential for maintaining the Rexroth A8V172’s performance. Here’s why quality matters:

While budget-friendly parts may seem like a viable option, they often come with hidden costs. Cheap parts may not withstand the high pressure and rigorous demands of an industrial hydraulic system, leading to early failures, increased downtime, and additional repair expenses. Inferior components can compromise the entire hydraulic system, resulting in significant productivity losses.

Investing in genuine or top-tier aftermarket parts ensures the hydraulic system’s reliability and reduces the frequency of replacements. Over time, quality parts lead to substantial savings by reducing operational disruptions and extending the pump’s lifespan. Quality components offer better resistance to wear and tear, even under intense working conditions, making them a smart investment.

To keep the A8V172 pump in peak condition, several core components are indispensable. Here, we’ll review the essential parts for repairs and maintenance:

Repair kits are comprehensive packages that include seals, gaskets, O-rings, and other critical components for addressing leaks and maintaining hydraulic pressure. These kits are specifically designed for the A8V172, ensuring compatibility and optimal performance.

Using a high-quality repair kit simplifies maintenance, ensuring all necessary parts are replaced simultaneously and reducing the likelihood of overlooking critical components.

Control valves are instrumental in managing the hydraulic system’s flow and pressure, contributing significantly to the A8V172‘s overall performance.

Hydraulic filters are critical for preventing contaminants from entering the system, protecting both the pump and the excavator’s other hydraulic components.

Maintaining proper filtration significantly reduces wear and ensures the hydraulic pump remains free from debris, promoting a longer lifespan.

Couplings are used to connect the A8V172 pump with other components, transferring power efficiently throughout the system.

Finding a reliable supplier for hydraulic pump repair parts is crucial. Quality parts from reputable suppliers ensure compatibility, durability, and reliability, which are essential for maximizing your pump’s efficiency.

When evaluating suppliers for A8V172 repair parts, prioritize factors such as reputation, product authenticity, and warranties.

The price of hydraulic pump parts can vary significantly, but investing in quality components pays off. Consider the following pricing factors:

Balancing quality with cost is essential. While it might be tempting to opt for cheaper alternatives, remember that quality parts contribute to long-term savings and operational efficiency.

Maintaining the Rexroth A8V172 hydraulic pump in your Sumitomo SH450-2 excavator requires a commitment to quality when choosing repair parts. By selecting components like durable repair kits, reliable control valves, effective hydraulic filters, and high-quality couplings, you can significantly enhance the performance and longevity of your pump. Working with reputable suppliers ensures you receive parts that meet industry standards, minimizing breakdowns and supporting the excavator’s robust functionality.

Regular maintenance and timely replacements are crucial. Invest in quality, work with trusted suppliers, and implement proactive care strategies to keep your hydraulic systems operating at peak performance.